Fine mechanical workshop is one of the core technical support platforms of ICPBR. The main equipment includes 3-axis machining center, precision type 5-axis high-speed machining center, turn-milling machining center, light-curing precision 3D printer, redial drilling machines, tapping machines, CNC grinding machines, CNC lathe and surface treatment machines etc. The platform has not only complete precision machining capability from raw materials to parts, but also rich experience in product design. It can quickly provide a variety of design, manufacturing, system integration and other overall solutions for research groups within the institute. We look forward to providing timely and satisfactory service to scientists and their teams.

JINGDIAO 3-Axis CNC Machining Center, Suitable for Milling Machining of Precision Mold Parts and Precision Hole Grinding of Metal and Special Materials.

|

Item |

Specification |

|

Max. Machining Accuracy |

5-20 μm |

|

X/Y/Z Travel |

600/500/300 mm |

|

Worktable Size |

650×650 mm |

|

Max. Load |

300 Kg |

Precision type JINGDIAO 5-axis high-speed machining center suitable for precision machining such as drilling, milling and grinding of complex shape metal hard materials (HRC > 50).

JINGDIAO high-speed precision spindle with torque of 21.5Nm is a standard component for JDGR400T, which meets the needs of using a wide range of tools to realize composite machining such as milling, grinding, drilling, boring and tapping and achieve 2 ~ 10 μm machining accuracy stably.

|

Item |

Specification |

|

Max. Machining Accuracy |

2-10μm |

|

X/Y/Z Travel |

450/680/400mm |

|

A/C Rotation Range |

-120°~90°/360° |

|

Worktable Size |

Ф400mm |

|

Max. Load |

150Kg |

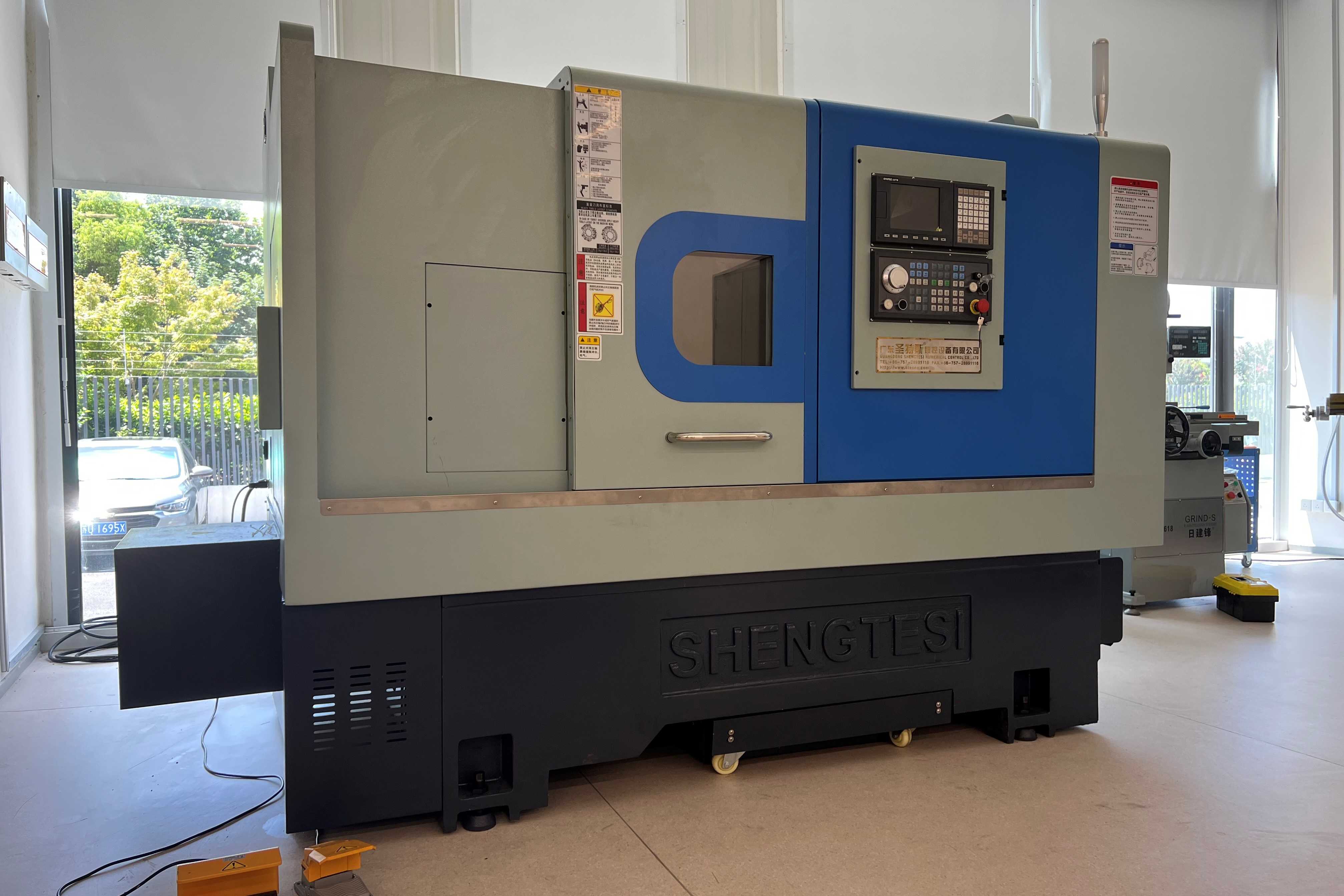

CNC Turret Lathe

1. The machine bed is an integrated cast high-rigidity bed with large anti-vibration damping and small deformation.

2. The 30° slant bed design makes it convenient for the operator to install and remove workpiece, and easy for chips removal.

3. Standard parts including servo turret, fast tool change and multi-tool positions.

4. Full-proof internal protection, effectively separating the machining area with better oil-proof, water-proof and dust-proof effect.

5. Tailstock has the function of fast forward and then slow forward.

6. Suitable for turning and milling multi-function workpiece.

|

Item |

Specification |

|

Max. Swing over Bed Diameter |

Ф350mm |

|

Max. Turning Diameter |

Ф350mm |

|

X/Y/Z Travel |

200/±45/550mm |

|

Tailstock Travel |

500mm |

|

Spindle Center Height |

1135mm |

Formlabs Stereolithography 3D Printer

|

Item |

Specification |

|

Technology |

Low Force Stereolithography (LFS)™ |

|

XY Resolution |

25 microns |

|

Laser Spot Size |

85 microns |

|

Laser Power |

Two 250 MW |

|

Build Volume (W x D x H) |

33.5 × 20 × 30 cm |

|

Layer Thickness |

25 – 300 microns |

Cai Yi (Eric)

Head of Fine Machining Workshop

Email: yi.cai@icpbr.ac.cn